New ultrasonic system

New ultrasonic system

ISO9001 certificate

ISO9001 certificate

EU CE certificate

EU CE certificate

In the past 20 years, we have always adhered to technological innovation and product upgrading as the initial intention, and the ingenuity in the ultrasonic field has helped enterprises improve efficiency and create value.

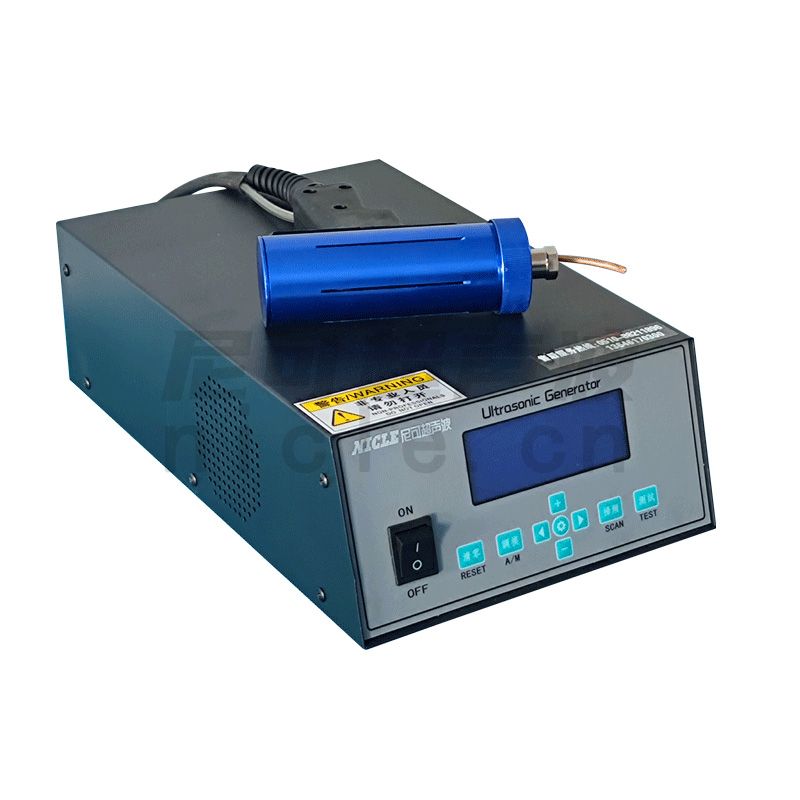

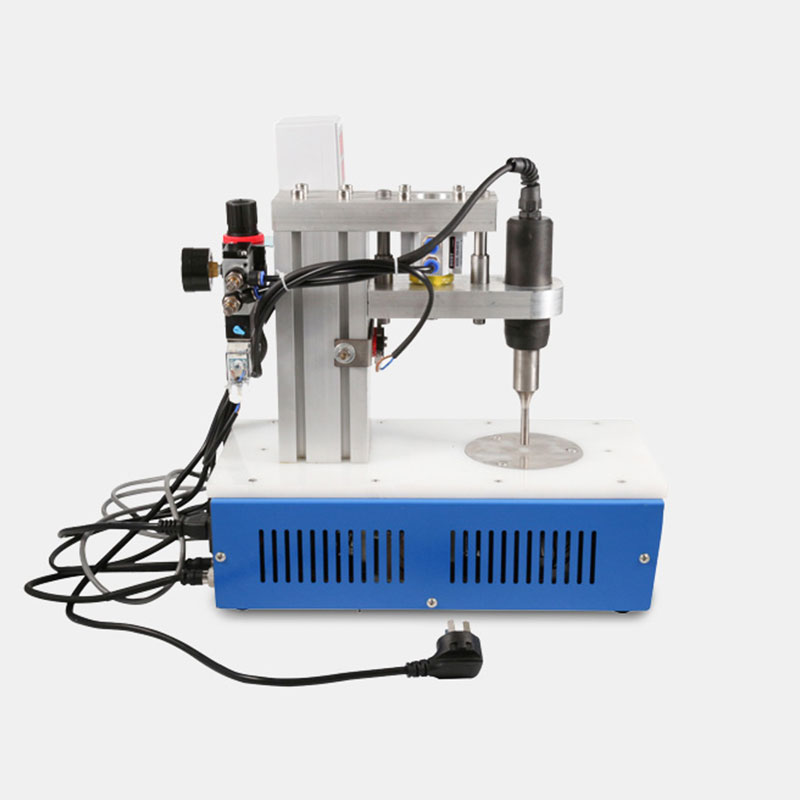

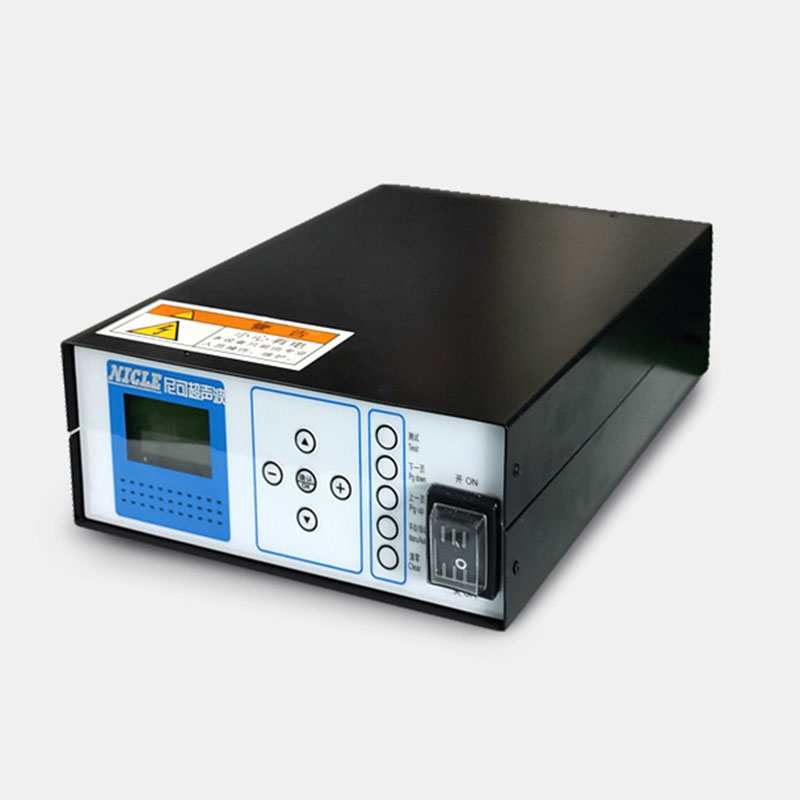

Hand held ultrasonic welding machine, also known as hand-held ultrasonic spot welding machine, ultrasonic spot welding machine, riveting welding machine and ultrasonic spot welding machine, can be used for butt welding of thermoplastic, and can also replace the welding head according to customer needs. It is used for riveting welding, spot welding, embedding, cutting and other processing processes. Compared with other traditional processes (such as adhesive, electric ironing or screw fastening, etc.), it has high production efficiency Good welding quality, environmental protection and energy saving.

View details

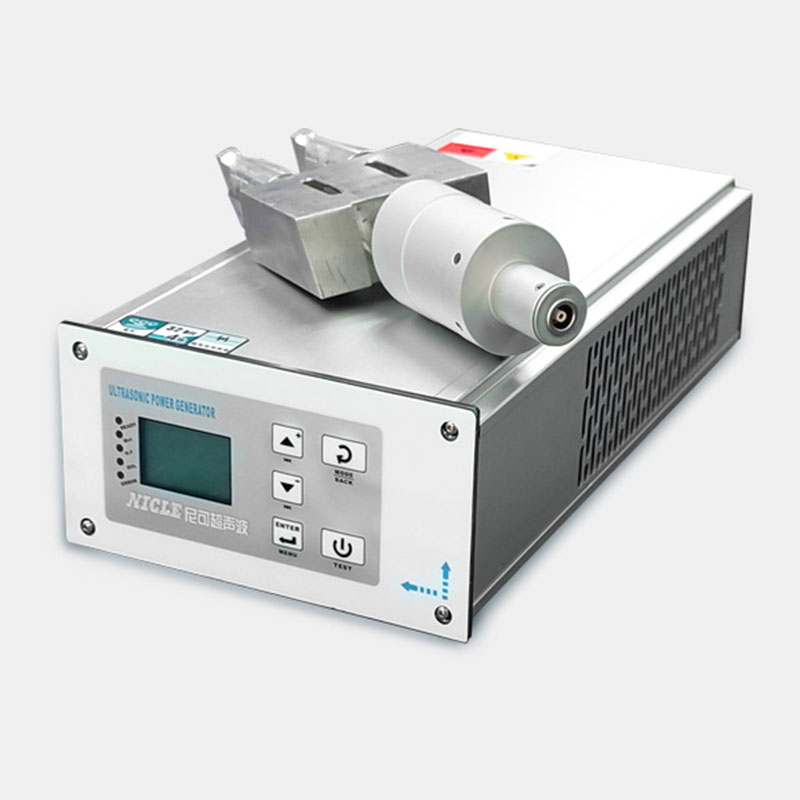

Ultrasonic plastic welding equipment is a high-tech technology for welding cooked plastic products. All kinds of cooked plastic rubber parts can be treated by ultrasonic welding. When welding plastic products, do not add any adhesive, filler or solvent, nor consume a large amount of heat source. It has the advantages of simple operation, fast welding speed, high welding strength and high production efficiency.

View details

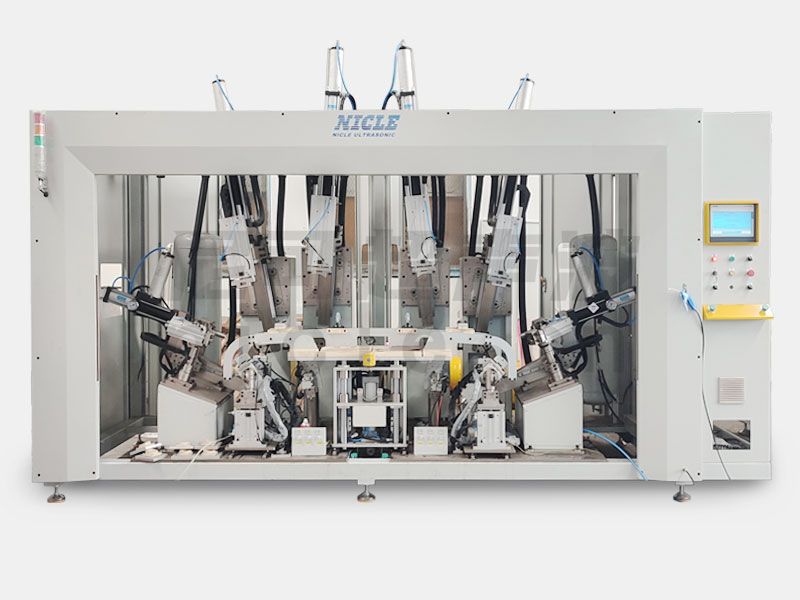

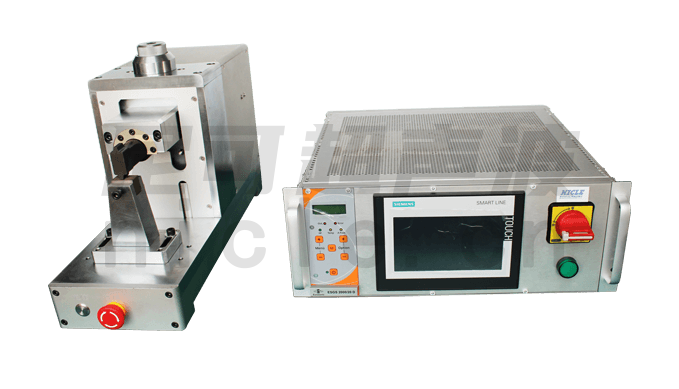

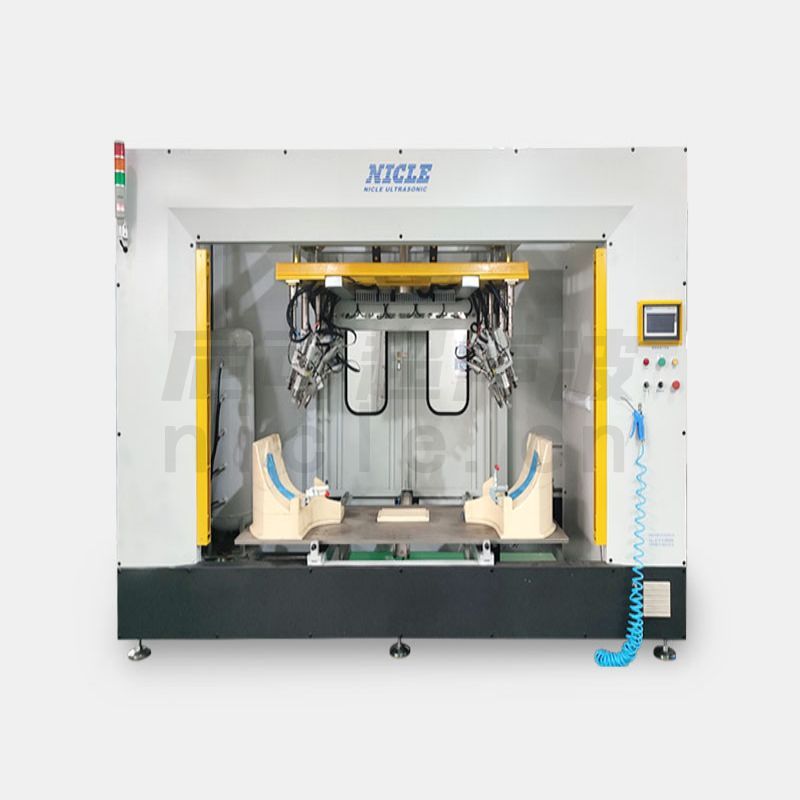

For the welding of automobile plastic parts, non-standard ultrasonic welding equipment, multi head and multi station design, with PCL program control and LCD operation, the welding of large automobile complex workpieces includes fusion surfaces in different directions, and multiple positions need to be welded at the same time

View details

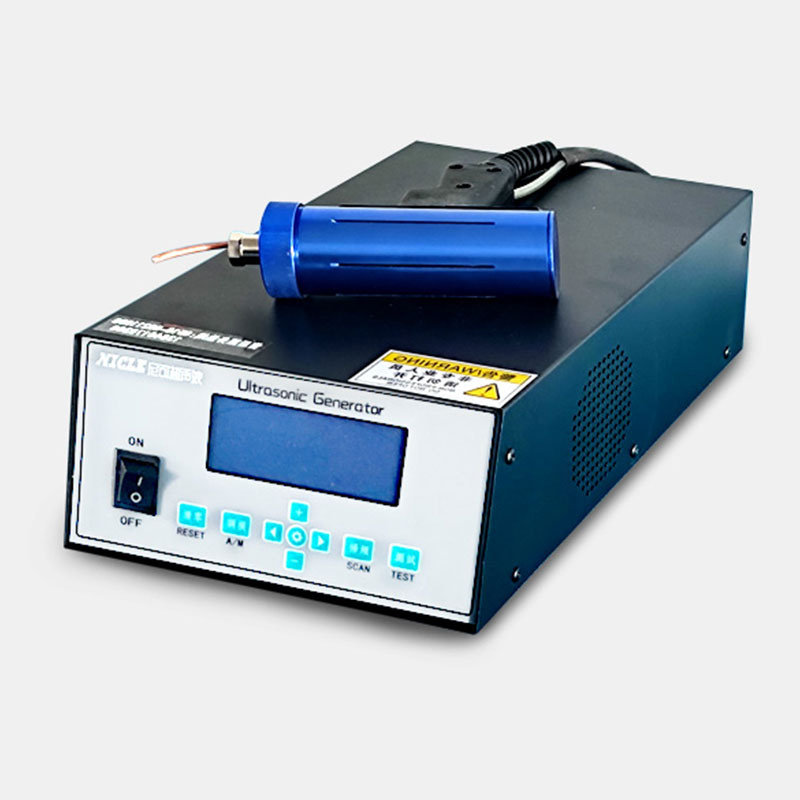

Ultrasonic wire harness welding machine uses ultrasonic friction principle to realize surface welding of different media, which is a physical change process. The high-frequency electric energy is converted into mechanical vibration through the transducer device, which acts on two metal surfaces to be welded. Under pressure, the two metal surfaces rub with each other at the main frequency, resulting in heat generation, condensation and fusion.

View details

When the thermoplastic material is heated by the heating element, the molecules reach the molten state. In a short time, the two plastic parts are pressed under a certain pressure and become one with each other through molecular movement. After cooling for a certain time, the two plastic parts will fuse into one and reach a certain fusion strength. In this way, the fusion function is realized.

View details

The hot melt welding machine adopts the extraction plate structure and the electric heating method. The whole machine is in the form of frame, which is composed of three large plates: upper formwork, lower formwork and hot formwork, and is equipped with hot mold and upper and lower plastic cold mold. The action mode is pneumatic control; The heating power and die size can be set according to different plastic parts size to realize the welding of a variety of plastic parts. The operation is simple and easy to use

View details

20 years of industry experience, rich in welding schemes

The equipment has obtained EU CE certification

Since its establishment, it has continuously improved the level of ultrasonic welding technology and the manufacturing capacity of ultrasonic welding equipment

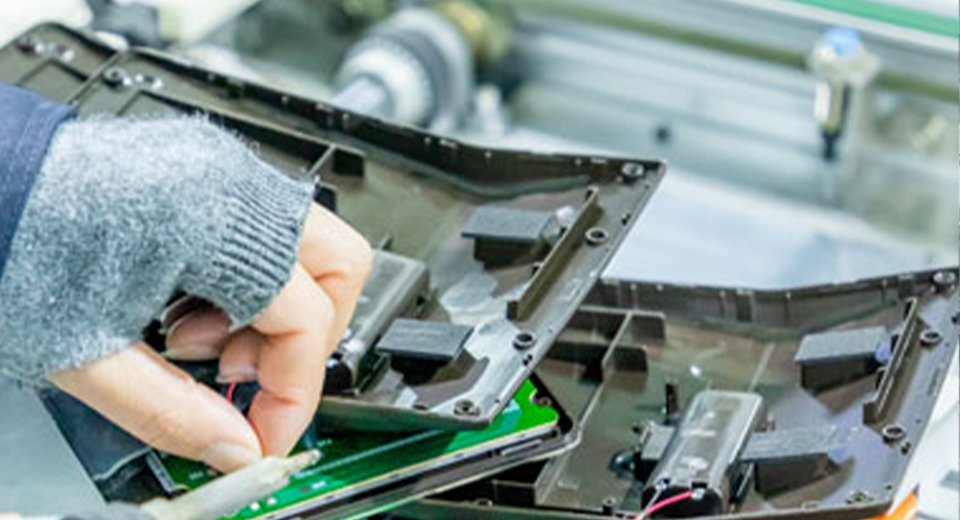

Strictly follow the quality control procedures and testing standards to ensure product quality.

All dimensions related to the machine can be customized according to user's requirements

20 years of ultrasonic technology precipitation, customized strength, trustworthy

Promise 1-year warranty and lifelong technical service support

Engineers conduct on-site maintenance within 12-48 hours on the same day in the province and outside the province

There are more and more plastic parts and interior trim parts in auto parts, whi···

View details

Plastic welding skills are needed in the production and processing of many produ···

View details

With the strong renewal of electronic and electrical products, the demand for we···

View details

Consult

client consultation

01

Consult

client consultation

01

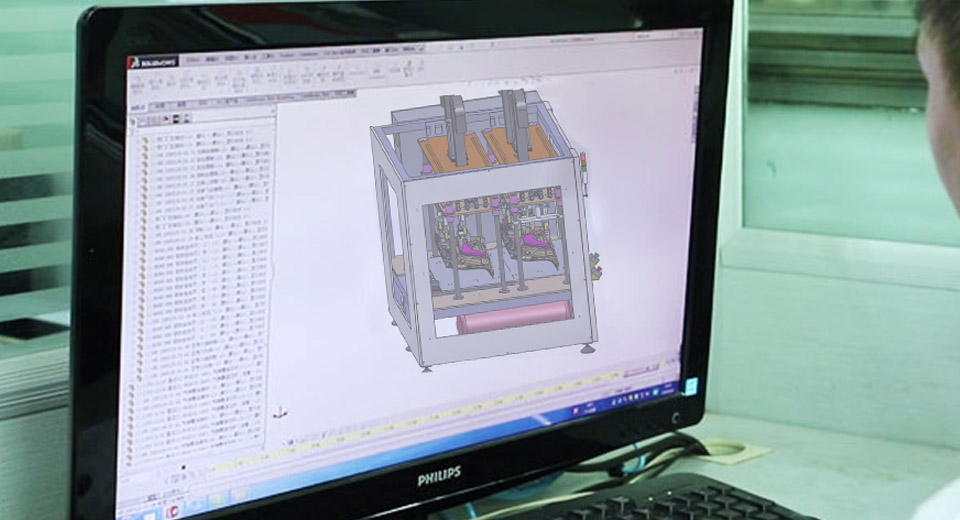

Product demand

Demand negotiation

02

Product demand

Demand negotiation

02

Sign a contract

signing the contract

03

Sign a contract

signing the contract

03

Production

Debugging products

04

Production

Debugging products

04

Inspection

Finished product inspection

05

Inspection

Finished product inspection

05

After sale

Confirmation of receipt

06

After sale

Confirmation of receipt

06

Ultrasonic vehicle plastic welding:Definition of ultrasonic welding: ultrasonic ···

Aluminum wire ultrasonic welding was first used in microelectronics, power engin···

2021-08-21

Nicle ultrasonic is mainly engaged in the production of ultrasonic plastic weldi···

2021-08-21Each set of welding heads and molds produced by ultrasonic mold processing facto···

Embossing equipment is divided into plastic embossing machine, non-woven fabric ···

2020-07-03

Ultrasonic welding is a high-tech technology for welding thermoplastic products.···

2020-06-30

1、 Setting of wave generation time: the specific time shall be determined accord···

2020-06-30

Principle of large plate drawing hot melt welding machine:The large-scale hot-me···

2020-06-30

Wuxi Nicle ultrasonic was established in 2004 and officially registered as Wuxi Nicle ultrasonic equipment Co., Ltd. in 2007. Located in Xishan Development Zone, Wuxi City, the company is mainly engaged in the R & D of ultrasonic welding and ··· 【View details】

216 Xitai Road, Xinwu District, Wuxi City, Jiangsu Province, China

181 6892 0913

chen@nicle.cn

Product Center

Product CenterMash welder Plastic welding Automobile Metal welding Hot plate welding Hot melt welding Hot riveting Ultrasonic mould

Contact Us

Contact Us

+86 18168920913